W6_Hassan Albarrami_ prioritizing work orders using Expected Monitoring Value (EMV)

1. Problem Definition

In my previous blog I have showed how to prioritize work orders biased on risk matrix. In this blog expected monitoring value is used to solve the same problem. According to business dictionary EMV is “Total of the weighted outcomes (payoffs) associated with a decision, the weights reflecting the probabilities of the alternative events that produce the possible payoff. It is expressed mathematically as the product of an event’s probability of occurrence and the gain or loss that will result” [4].

2. Identify the Feasible Alternative

Four different preventive maintenance orders to be prioritize

- Lube oil pump for SYN gas machine

- Control valve in boiler B

- Methanol transfer pump C

- Steam Turbine lube oil pump B

3. Development of the Outcome for Alternative

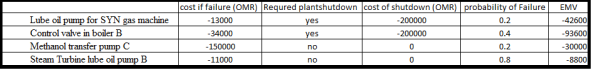

Table1 is showing different consequence of cost and the probability of failure for each alternative.

Table 1 EMV calculation

Expected monitoring value (EMV) also calculated in the same table using the following formula

EMV(Z) = P(Y1)X1 + P(Y2)X2 + … + P(Yn)Xn……………………..[3]

Where :

- Y1, Y2, Yn represent a set of possible outcomes of some uncertain variable

- X1, X2, Xn represent the NPVs associated with each of the possible outcomes

- P(Y1), P(Y2), …, P(Yn) represent the probabilities of each of the outcomes

4. Selection Criteria

Maximum EMV value will be selected

5.Analysis and Comparison of the Alternative

From the table both SYN gas machine and control valve failure are resulting massive cost if happened but their probability is very low their EMV is (-42600 and -93600). Methanol transfer pump is costing major number also but still its probability to happen is low as will its EMV is (-30000). Steam turbine oil pump is costing less than the other equipment but its probability is relatively high its EMV is (-8800).

In this problem EMV (-8800 ) does not represent the cost coming from turbine oil pump if failed, in fact the cost if failed will be 11000 as mention in the table above. That is to say EMV is giving you logical numbers only to help you taking decisions.

6. Selection of the Preferred Alternative

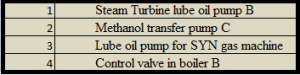

From the results the priority of orders will be as following

7. Performance Monitoring and the Post Evaluation of Result

The management has to reassess the list of equipment in terms of criticality every year and to find logical way to calculate the probability of failure for all equipment. And it is very important to identify the actual cost in the market for all equipment especially critical ones.

Reference

- Prometheusgroup.com, Equipment Criticality and the Prioritization of Work Orders, Retrieved on 06.07.2014 fromhttp://www.prometheusgroup.com/kindle/conference/Equipment-Criticality.pdf

- Plant-maintenance.com, Defining Work Order Priorities, Retrieved on 06.07.2014 fromhttp://www.plant-maintenance.com/articles/WOPriorities.pdf

- E-education, Expected Monetary Value and Value at Risk, Retrieved on 13.07.2014 fromhttps://www.e-education.psu.edu/eme801/node/578

- Business dictionary, Expected Monetary Value, Retrieved on 06.07.2014 fromhttp://www.businessdictionary.com/definition/expected-monetary-value.html

OUTSTANDING, Hassan!!! Almost guaranteed you will see an EMV problem on your PMP exam and as you can see, it actually is quite a useful tool, especially when it comes to RISK MANAGEMENT.

Reference my handouts from Day 2, slide #45. Look closely at Columns G, H, K and I on the spreadsheet OR open up the risk analysis your team created as part of your project plan.

Bottom line- excellent case study and you followed our step by step process very well. Keep up the good work.

BR,

Dr. PDG, Jakarta

Thanks Dr.